Community Profile: Town Hangs On to Old Economy Even as It Embraces the New

Photo Gallery | Article

Photo Gallery - Bedford/Lawrence County, Ind.

GM is investing more than $100 million in its Bedford plant. The "extreme manufacturing makeover" became necessary when GM decided that Bedford would make all of the cylinder heads for a new engine. The Bedford plant was picked for this job after management and the union worked together to streamline work rules. Photo by Susan C. Thomson

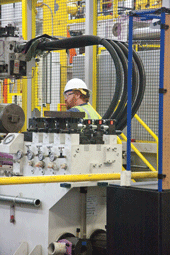

Skilled maintenance worker Justin Wells performs an inspection on one of the GM plant’s new state-of-the-art die-casting machines. Photo by Susan C. Thomson

Dave Hunt (left), a skilled maintenance worker, confers on the floor with the GM plant’s finance manager, Glenn Sampson. Photo by Susan C. Thomson

Two of the 17 new machines planned for the GM plant as part of its $111 million renovation. Photo by Susan C. Thomson

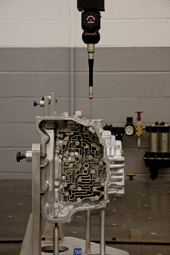

For quality control at GM, a special device measures a new housing down to 0.01 millimeter. Photo by Susan C. Thomson

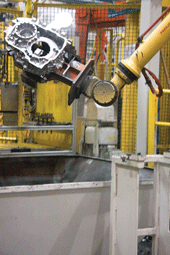

At the GM plant, a robot removes a die-cast transmission housing from one of those machines. Photo by Susan C. Thomson

At Elliott Stone Co., Lucas Nikirk uses airbags to detach limestone blocks weighing as much as 15 tons each from the company’s underground quarry. The company machines them into building stones and various specialty products. Photo by Eric Rudd Photography

A former public school, built in Romanesque style of Indiana limestone in 1899, sits in a residential Bedford neighborhood. The city had hoped to use part of a state grant to convert the school into housing. But the money didn't come through. Photo by Susan C. Thomson

Downtown is being eyed by the city for updates, including new lighting, signs and plants. The city had hoped to win a state grant to convert a school and the two-story building on the downtown corner to housing. The city didn’t get the grant and is now pursuing other sources of funds to accomplish those goals; meanwhile, the private owners of the two buildings have listed them for sale. Photo by Susan C. Thomson

At Bedford Machine & Tool Inc., Richard Hawkins polishes steel inserts for a die. Photo by Susan C. Thomson

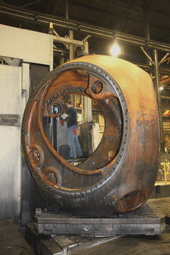

The machining of iron housings for wind turbines is one of the new services that Bedford Machine & Tool offers. Traditionally, most of its business came from GM and other auto-related businesses. Photo by Susan C. Thomson

The Great Recession came early and hard to Bedford, Ind. Visteon Corp. closed its plant in 2008, a year after Dana Corp. shut down its operations in nearby Mitchell. The departures wiped out 1,300 jobs and left the General Motors aluminum die-casting plant as Bedford's only major survivor of the once-thriving local auto-parts industry.

The 915,000-square-foot GM complex has been a community fixture since the early 1940s. But by the time of the latest recession, its impact had already been greatly diminished. Though highly automated, it was down to making only transmission cases and housings. Employment had dwindled by more than two-thirds from its peak about 30 years ago. Further clouding the plant's future, its parent company was restructuring after emerging from bankruptcy.

To head off a possible closing, the plant's management and representatives of the local unit of the United Auto Workers "worked very closely and together" to streamline the plant's work rules, said plant manager Eric Gonzales. By making the plant more efficient, they hoped to ensure its survival.

Their strategy paid off. A year ago, GM picked Bedford over other plants contending to make all of the cylinder heads for a new engine going into the company's next generation of lighter trucks and sport utility vehicles. To that end, the plant is now undergoing what Gonzales described as "an extreme manufacturing makeover." Walls are coming down, ceilings are being raised and floors are being cleared to prepare the way for new casting robots. The company has promised to create 245 new jobs over the next couple of years.

In return for GM's $111 million investment, the Indiana Economic Development Corp. promised the company up to $2.5 million in income tax credits over 10 years. The city of Bedford pitched in, agreeing to a 10-year phase-in of local taxes on the new machinery.

Tax Breaks

The city has granted the same kind of tax breaks to two promising newer businesses as they, too, have invested in new equipment. They were started by Tom Miller in one case and by Doug Conrad and Larry Parsons in the other. All three are former GM engineers.

Miller developed a pump system used in geo-thermal heating and cooling applications for homes and businesses. In 1986, he started Geo-Flo Products Corp. to make his product, and in 2000 he moved his company from Bloomington, Ind., to Bedford. It has since expanded there twice, most recently more than doubling the plant's footprint to more than 50,000 square feet.

Conrad and Parsons co-own Bedford Machine & Tool Inc. In the beginning, 23 years ago, GM and various auto-related customers accounted for about 80 percent of the specialty manufacturer's sales, Conrad said. As the company has grown, it has diversified into other lines of work, including the machining of iron housings for wind turbines. The company turns out four or five a week, each weighing 18.5 tons.

These remain small companies, Bedford Machine & Tool with 70 employees, Geo-Flo with only 13. Nevertheless, they show Bedford "revamping our old way of doing things and entering new markets," notably green energy, said Gene McCracken, executive director of the Lawrence County Economic Growth Council.

For immediate impact, the city's stand-out new market has been defense. The Crane naval base, one county away with 6,000 employees, is said to have been a magnet for the new business. Doug Kellams, head of a Bedford construction company, gets credit for being the catalyst. Fearing that the 285,000-square-foot Visteon plant would "just sit idle and then deteriorate" and wanting to do "something for the community," he took "a leap of faith" and bought the property for $3 million as Visteon was clearing out.

He renamed it the East Gate Business & Technology Center and then managed over just the past 2½ years to lease 80 percent of it. There are two major tenants. Bedford-based Tri-Star Engineering, which provides engineering and other management services for defense and other clients, moved in with 40 employees and has since expanded to 200. Science Applications International Corp. of San Diego, Calif., came new to Bedford with 60 employees; today, there are 300 workers. They install communications equipment in military vehicles. This has all happened without benefit of any economic incentives, either for Kellams' building purchase or his tenants' moves.

Limestone Capital

The community is "alive with entrepreneurial spirit" these days, said Kenneth H. Frye, a Bedford-based regional executive vice president with German American Bancorp. It's the same spirit that gave birth to the local limestone industry in the early 1800s, he said.

Bedford lies amid a three-county region of southern Indiana that boasts some of the world's richest deposits of dimensional limestone, the sort that can be fabricated into building material. With dozens of quarriers and fabricators employing thousands of employees altogether, limestone remained the area's leading industry until the mid-20th century, according to Jim Owens, executive director of the Bedford-based Indiana Limestone Institute of America. He estimates that, due mostly to automation, the regional industry is down now to approximately 20 companies and a total of 1,000 workers.

The city still bills itself as the Limestone Capital of the World. The Lawrence County Tourism Commission promotes the idea with its web site (www.limestonecountry.com) and a self-guided "limestone trail" tour of buildings, museums, stone works and views of abandoned quarries.

In a 30-year plan done for the city last year, a consulting firm recommended that Bedford put the 13 abandoned quarries within the city limits to some sort of recre-ational use and consider developing an outdoor limestone museum. The plan also noted opportunities for civic improvement in the city's dated downtown, aging housing stock and infrastructure, and lack of affordable housing.

The city wrapped some of those suggestions into its own plan calling for, among other initiatives, creating miles of walking trails, converting some buildings into low-income housing, enhancing waste-water treatment, improving flood control, restoring an obsolete rail spur to the GM plant and dressing up downtown with new signs, plants and lights.

Bedford entered its plan in Indiana's first competition for two special development grants to small communities, hoping for about $15 million over the next three years. Though one of 12 finalists, the city didn't win. Mayor Shawna Girgis said the city was exploring alternative sources of funds, including other state grants, to finance some of the projects. Increases in GM's property taxes could possibly be set aside to restore the rail spur, she said.

McCracken described the spur as key to industrial development in general and, specifically, to any possible further expansion of the GM plant, which will still have space to spare when the current renovation is completed. Even as technology makes it possible for plants to do more work with fewer people, manufacturing remains crucial to Bedford's economy, he said.

"A Step Ahead"

The city's planning consultants foresaw proportionately fewer future jobs in manufacturing and more in the professions, sciences, technical fields, social services, real estate and health care in the coming years.

Health care is already a conspicuous growth industry. Bedford has two hospitals, both "critical access," a special category of rural hospitals qualifying for extra Medicare reimbursement and limited to 25 beds each. St. Vincent Dunn Hospital has about half the employees of Bedford Hospital, which is affiliated with Indiana University Health. President Brad Dykes said it has increased its staff by 10 percent over the past 10 years.

Bedford's unemployment rate hovers a point or so above the national average. But Jack A. Kenworthy, president of Bedford Federal Savings Bank, noted that it dropped by 1.3 points over the past year. That decline, along with the new jobs at the East Gate Business & Technology Center and the promise of more still at the GM plant, shows that the local economy is improving, he said.

McCracken acknowledged challenges ahead. "We've got to replace what we've lost and grow with the new and emerging," he said.

At the same time, he saw an advantage in the area's early and rough experience with the recession. "We're a step ahead because we started facing challenges before everybody else," he said.

Bedford/Lawrence County, Ind., by the numbers

| POPULATION |

13,413/46,134 (1)

|

| LABOR FORCE |

NA/21,896 (2)

|

| UNEMPLOYMENT RATE |

NA/10.7 percent (2)

|

| PER CAPITA PERSONAL INCOME |

NA/$29,626 (3)

|

| (1) U.S. Bureau of the Census, 2010 census | |

| (2) BLS/HAVER, December 2010, seasonally adjusted | |

| (3) BEA/HAVER, 2008 | |

| Largest Employers | |

| North Lawrence Community Schools |

800 (4)

|

| Indiana University Health-Bedford Hospital |

550 (4)

|

| General Motors |

400

|

| Wal-Mart |

334 (4)

|

| Scientific Applications International Corp. |

300

|

| (4) includes part-time employees | |

Views expressed in Regional Economist are not necessarily those of the St. Louis Fed or Federal Reserve System.

For the latest insights from our economists and other St. Louis Fed experts, visit On the Economy and subscribe.

Email Us