Community Profile: Murray, Ky., Bucks Trends in Manufacturing

|

|

||

|

Murray, Ky. |

||

| BY THE NUMBERS | ||

| Population | ||

| City 15,538 (2005) | ||

| County 35,122 (2005) | ||

| County Labor Force | ||

| 17,595 (October 2006) | ||

| County Unemployment Rate | ||

| 4.2 percent (October 2006) | ||

| County Per Capita Income | ||

| $22,422 (2004) | ||

| Major Employers | ||

| Murray State University | 1,400 | |

| Pella Inc. | 1,000 | |

| Briggs & Stratton Inc. | 1,000 | |

| Murray-Calloway County Hospital | 850 | |

Murray, Ky., is a contrary place. While the nation’s manufacturing muscle has been wasting, the town and surrounding Calloway County have been bulking up together, adding about 300 manufacturing jobs between June 2001 and June 2006, according to the Bureau of Labor Statistics. Put another way, during a period in which the United States lost 14 percent of its manufacturing jobs, the number of manufacturing jobs in Calloway County increased by about 10 percent.

The 3,300 manufacturing jobs in June 2006 accounted for about 20 percent of all of the area’s jobs, double the national percentage. Service industries such as retailing and education employed more people, but manufacturing accounted for a disproportionate 23 percent of the area’s wages.

That makes manufacturing a big driver of the local economy, says Mark A. Manning, president of the Murray-Calloway County Economic Development Corp. “The community could survive without much manufacturing. But the community cannot thrive without much manufacturing.”

By all outward signs, Murray-Calloway County—frequently hyphenated and spoken of in one breath—is thriving. The unemployment rate tended to be below the state’s all last year. Homes in the county sold last year for an average of $123,577, compared with $115,940 in 2005, according to local real estate agent Kathy Kopperud.

The area is witnessing “as big a building boom as we’ve had in our history,” says Tab Brockman, executive director of the Murray-Calloway County Chamber of Commerce. A $40 million addition in the works at Murray-Calloway County Hospital will nearly double its size. Murray State University is constructing a $13 million residence hall and a $50 million science building. A 72-room Hampton Inn will open in a few months.

Toys R Us No More

The growth is all the more striking given the pullout of Mattel Inc. A mainstay manufacturer since 1973, the company announced in April 2001 that it would phase out its Murray plant, its last in the United States, and move the production of riding electric toys to Mexico.

Keith Travis, now vice president for human resources at the hospital but then the head of human resources at Mattel, recalls the meeting at which the employees got the bad news. “You could hear the breath go out of people. … You could see people’s lives change.”

The rest of the community took hard the prospect of losing, in one devastating smack, 1,000 manufacturing jobs and their $30 million in annual payroll. Those jobs accounted for close to one-third of all area manufacturing jobs at the time.

|

Pella |

Sure, there was still Briggs & Stratton, the town’s other major manufacturing citizen, accounting for another 1,000 or so jobs at its engine-making plant in Murray, plus a smattering of smaller industries. Rather than rest on what was left, community leaders got together and took immediate steps not just to recover but to grow. They cut the Economic Development Corp. loose from the Chamber of Commerce, which had shared staff and an executive director, and hired Manning to head up the newly independent EDC.

He arrived that August, while Mattel was winding its factory down and the area’s economic future appeared to hang ominously in the balance. Unbeknownst to him or anybody else there then, Pella Corp., the Iowa-based maker of doors and windows, was already scouting Murray for the site of a new plant.

Finally, in June 2002, in a ballroom at Murray State, came the nick-of-time public announcement, followed by a huge public sigh of relief: Pella had chosen the area for its new operation and would immediately begin setting up for production in a 733,000-square-foot building that Mattel had almost finished vacating.

University’s Role

That building’s availability was one factor in that decision, according to Jim Nieboer, who headed the company’s site selection committee. He says the company also weighed operating costs and the quality of local labor, leadership, schools and amenities. (The Murray area, like so many other communities, also uses state grants and local incentives to attract businesses.) Nieboer singled out Murray State, which he said is not widely known for being involved in economic development. “But it was very evident that the university plays a vital role in driving regional economic growth.”

|

Murray State |

The EDC promotes that role by reserving one slot on its 12-member board for a university representative. The university puts its weight behind EDC initiatives by, for instance, hosting prospective employers and, in Pella’s case, providing space for the company’s big announcement and its interviews with job candidates as well as temporary on-campus housing for its executives.

Just by being there with its 10,300 students, Murray State contributes to the local economy in many ways—for one thing, cushioning it against recession, says Ronnie Gibson, chairman of the EDC board and of the $170 million-asset Murray Bank. A growing number of well-off retirees, immigrants from as far off as California, also add economic stability. He recalls the trend starting with a big influx of them after Rand McNally named Murray the top U.S. retirement community a couple of decades ago.

For all its progress of late, the area remains restfully small-town, rural and outdoorsy. Downtown Murray’s centerpiece is a classic old-time courthouse square, some of its buildings dating back more than a century. Depending on the season, fields just outside of town grow green with soybeans, corn, winter wheat and tobacco, once the area’s prime crop, its acreage now limited by the national tobacco settlement.

Within a half hour’s drive lies Land Between the Lakes, formed in the 1940s when the Tennessee Valley Authority dammed the nearby Tennessee River, creating Kentucky Lake and Barkley Lake. The area remains a vast and largely undeveloped land-and-water playground.

|

Webasto |

Today, TVA provides parts of seven states, including southwestern Kentucky, with electricity that’s inexpensive, relative to what’s paid in many other parts of the country. That was “a big deal” to Webasto Roof Systems Inc. when it was comparing locations for a new plant, says John Gragg, commercial manager for the company’s Kentucky operations. A railroad spur, abandoned since Mattel decamped, also helped sway the company’s decision to build a 110,000-square-foot plant in Murray, he says.

The plant, a stamping facility for automobile sun roofs, began gearing up for production not quite two years ago and now has close to 100 employees. Gragg says the company, a unit of automotive equipment maker Webasto AG of Stockdorf, Germany, is still in the building-up phase in Murray and hopes to get “bigger and bigger” there.

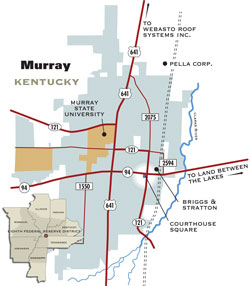

Webasto joined two trucking companies, a medical supplies distributor and a textbook wholesaler in the EDC’s industrial park north of town just east of Highway 641, the area’s north-south axis. With only 10 of the park’s more than 80 acres left now, the EDC has taken options to buy 150 acres for industrial development west of the highway.

Meanwhile, a little more than a mile to the south, Pella is going great guns, having fulfilled its promise of 500 jobs after just two years of operations. More than 1,000 people now work at the automated plant, one out of nine of the company’s total workforce. On two full shifts and a partial third, they run machines that do everything from cutting glass to wrapping finished vinyl and fiberglass windows in plastic for shipping.

Pella has turned out to be better than community leaders could have hoped for, says Manning, because it offered jobs with better pay and benefits than Mattel did. In an expression of appreciation, the county renamed the street leading into the plant—from Poor Farm Road to Pella Way.

|

Briggs & Stratton |

The Little Engine That Could

And there is still Briggs & Stratton. The Milwaukee-based company, weathering a rough patch owing to a drop in demand for its engines, shut down the Murray plant’s third shift, laying off 110 workers in January. Even so, almost 1,000 remain, making the company just as critical to the local manufacturing economy as it was in the Mattel days.

With Briggs & Stratton and Pella the twin stalwarts now, it’s still very much a two-company economy. Even with Webasto and an incrementally growing group of smaller industries in fields like chemicals, food- processing and plastics varying the mix in the past six years, Manning worries about “too many eggs in too few baskets.” To spread the risk, he says, “we need five to six more companies in (Webasto’s) size range with good product diversity.”

Views expressed in Regional Economist are not necessarily those of the St. Louis Fed or Federal Reserve System.

For the latest insights from our economists and other St. Louis Fed experts, visit On the Economy and subscribe.

Email Us