How COVID-19 Disrupted Global Value Chains

You might not be the only one finding it difficult to get your hands on a new iPhone 13 this holiday season.

That’s because Apple reportedly was likely to cut production of the device by up to 10 million units due to chip shortages in the electronics supply chain. Because the iPhone is made with hundreds of parts sourced in 43 countries, many have been difficult to obtain. That’s impacting production and Apple’s iPhone manufacturer in China expects the crunch to continue until the second half of 2022.

Apple’s struggles are an example of how global value chains have become fragmented and susceptible to shocks.

A global value chain breaks up the production process across countries, according to the World Bank (PDF). Firms specialize in a specific task and do not produce the whole product. That’s different from a supply chain, which represents the steps it takes to get the product or service to the customer, according to Investopedia.

In a Review article, St. Louis Fed Senior Economist Ana Maria Santacreu, Senior Economist Fernando Leibovici and Research Associate Jesse LaBelle examined how global value chains are structured, the pandemic’s effects on them and possible solutions to make them more resilient.

The article, “Global Value Chains and U.S. Economic Activity during COVID-19,” was published in the third quarter 2021 issue of the St. Louis Fed research publication. Santacreu also discussed rethinking global value chains in a May 11, 2021, presentation (PDF) for a virtual event hosted by the St. Louis Fed’s Louisville, Ky., Branch.

The Gains and Risks from Sourcing around the World

Global value chains’ specialization at each stage benefits the production process, according to Santacreu’s May 2021 presentation. This could mean a chain has lower production costs, is able to better source raw materials or has advanced technology, all of which result in productivity gains.

They also lead to long-term relationships between the firms involved in the production process, Santacreu noted. Because production enhancements often require large investments upfront, firms must develop strong relationships to ensure production remains robust.

However, if any disruption occurs, such as the COVID-19 pandemic that impacted chains around the world, the shock can significantly affect industry production and economic output in any global value chain stage.

Global value chains have become more important over the years, meaning the world’s supply chain has become more fragmented. Since 1970, global value chains’ share of global trade had grown by more than 10 percentage points in 2015, according to the World Bank’s 2020 World Development Report and cited in Santacreu’s presentation.

COVID-19 Challenges: Shipping, Trade Restrictions, Lockdowns

The pandemic created three key problems for global value chains, Santacreu said in her presentation. Those include:

- Shipping costs increased

- Exports were curbed on essential medical goods

- Global lockdowns disproportionally impacted industries that rely heavily on global value chains

Shipping costs have risen exponentially due to the shortage of containers and government social distancing restrictions. According to international freight marketplace Freightos and its global container index, the market rate to ship a 40-foot container on Jan. 3, 2020, was $1,461. That number rose by 540%, to $9,351 on Nov. 26, 2021.

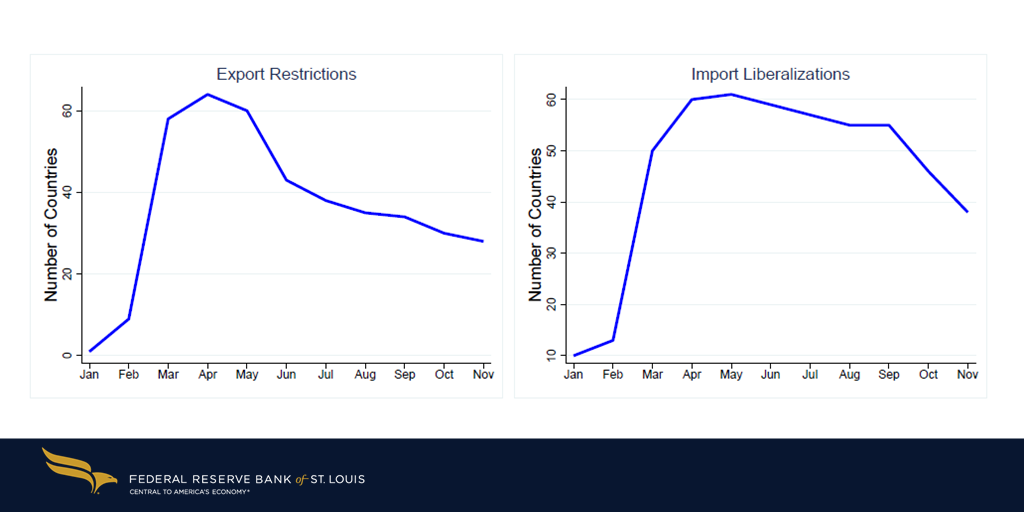

COVID-19 also led to increased demand for pharmaceutical ingredients and medical equipment and to government restrictions on trade that created shortages. Because only a few countries specialize in the production of key equipment, such as respirators, many countries relied on imports, according to Santacreu’s presentation. Therefore, governments of exporting countries started enforcing trade restrictions to avoid supply shortages. (See line graphs below.) As trade restrictions increased around the world, global value chains had to cope with fewer products supplied.

Trade Policies on Essential Medical Goods Changed in Early 2020

SOURCES: “International Trade Policy during a Pandemic,” a 2020 working paper by Leibovici and Santacreu, with data from Global Trade Alert.

Lastly, some industries were affected more than others by global lockdowns. Industries with a higher share of “value added,” or materials, inputs and tasks, from countries with stricter lockdown policies are likely to be more exposed to foreign shocks, the authors wrote. For example, the U.S. motor vehicle industry has been hit hard by the pandemic. That’s because 24% of the industry’s exports embody foreign value added, with main suppliers in China, Mexico, Japan and Canada, according to Santacreu’s slide presentation. The industry’s struggles have affected its employment and production.

Rethinking the Chains: Barriers and Benefits

Due to the deep shocks felt around the world, many are rethinking the structure of global value chains, Santacreu said. Experts want to increase stability and resilience without losing efficiency gains. Two ways to do that, the article outlined, are by diversifying to include more countries as additional suppliers or by moving more global supply chains to the U.S. from big countries like China.

But there are barriers to overcome.

- There would be high costs associated with restructuring. Establishing long-term relationships with new firms would involve incurring high fixed costs according to Santacreu’s presentation.

- In addition, some inputs are specific to a region or supplier, such as rare metals sourced in China to produce semiconductors like those found in Apple’s iPhone. Because those materials are not available in many countries, a domestic restructure would be challenging.

- Even if those two problems were solved, it could take time to scale up production, Santacreu wrote.

She also suggested short-term solutions, temporary measures to improve production, including government involvement to increase production in the private sector.

Medium-term solutions include the appropriate stockpiling of inputs and products so that when the next shock hits, chains are prepared. Also, critical sectors should build up supply chains to avoid heavy dependence on foreign inputs if a crisis should arise, Santacreu wrote.

All solutions require international cooperation through trade agreements. As a result, global value chains would have a more fluid and functioning supply of materials prepared for the next shock.

This blog explains everyday economics and the Fed, while also spotlighting St. Louis Fed people and programs. Views expressed are not necessarily those of the St. Louis Fed or Federal Reserve System.

Email Us